FEATURES AND BENEFITS OF COAXIAL VALVE TECHNOLOGY

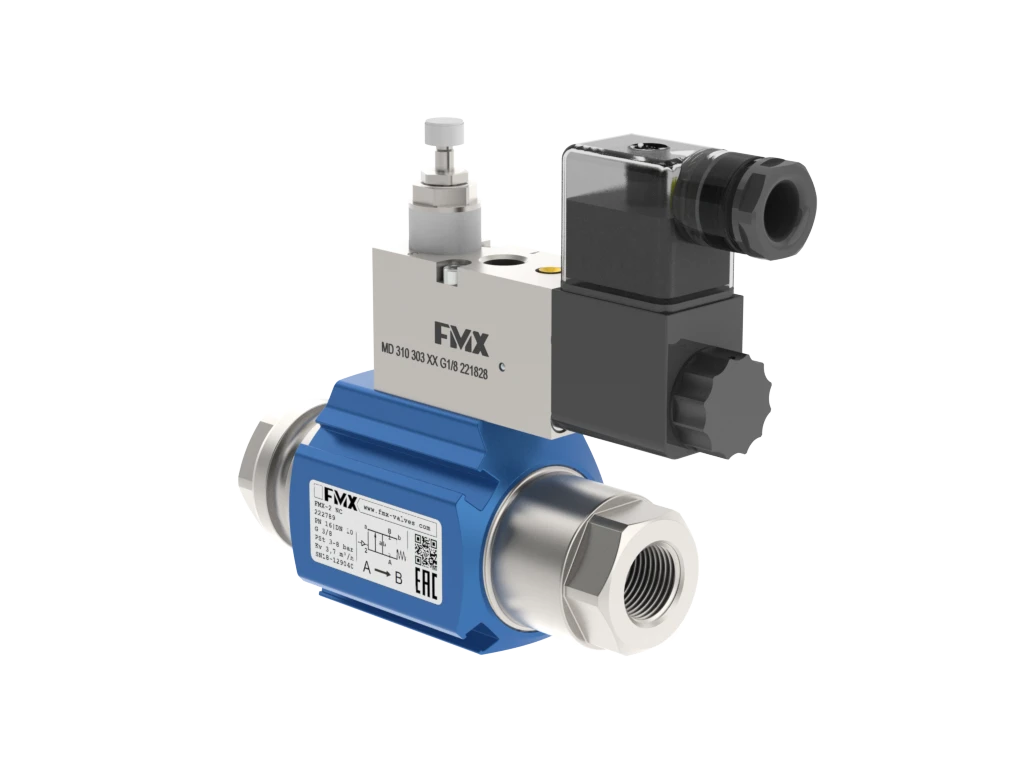

PRESSURE BALANCED

Due to the pressure balanced valve design, the system pressure or Δp has no effect on the switching forces

Unlike conventional valves, coaxial valves require no minimum differential pressure in order to function > operating from 0 bar

Whether controlling vacuum or high pressure valve performance remains precise and dependable

High pressures can be switched with low energy consumption

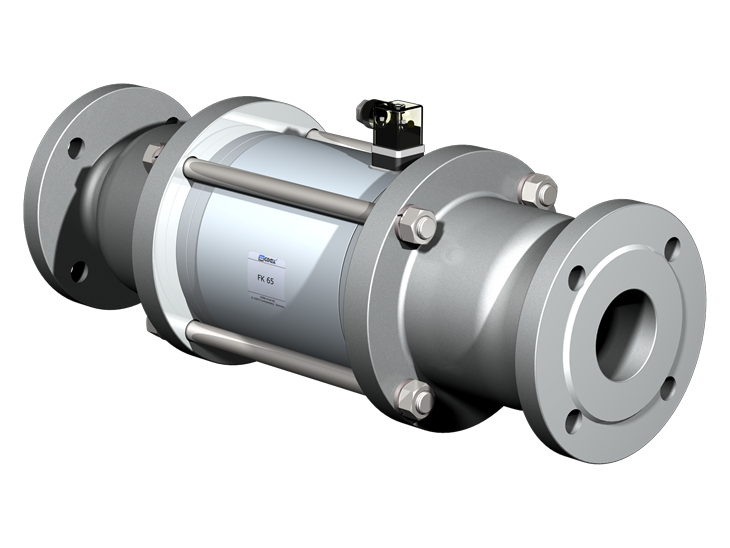

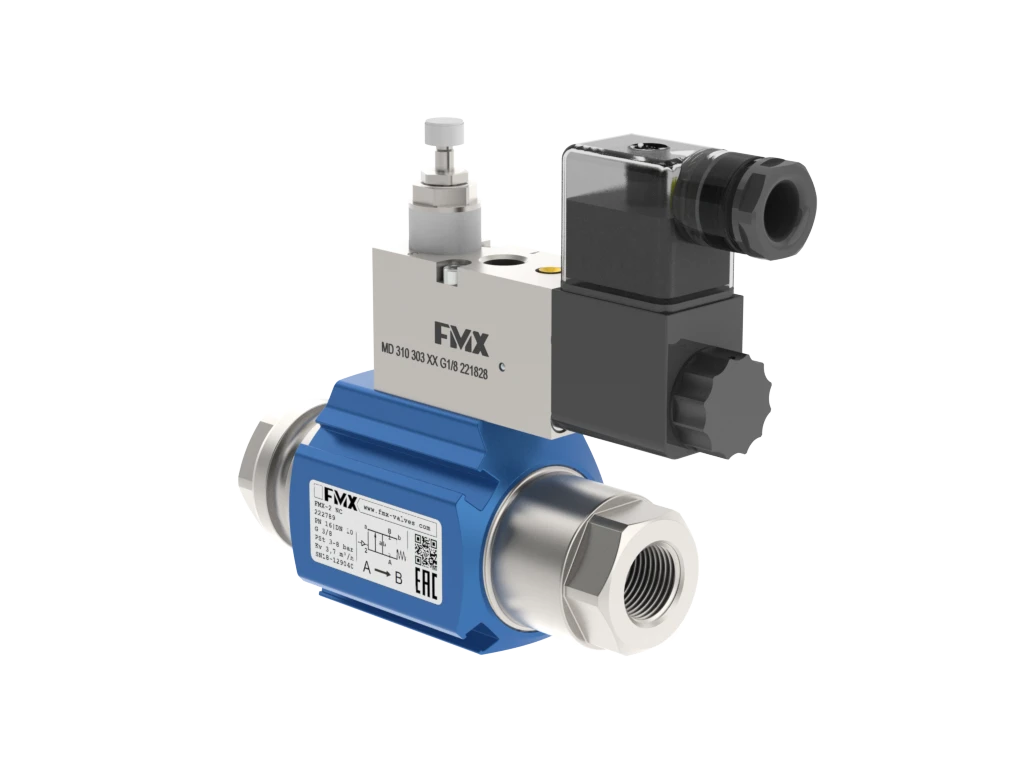

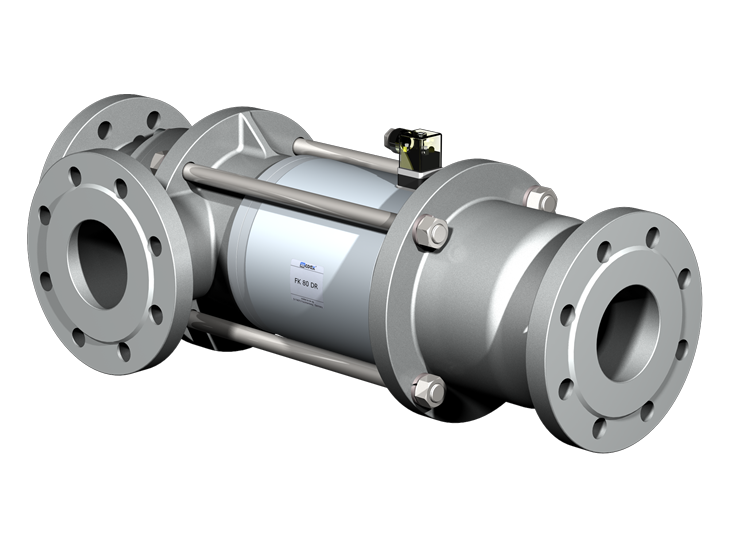

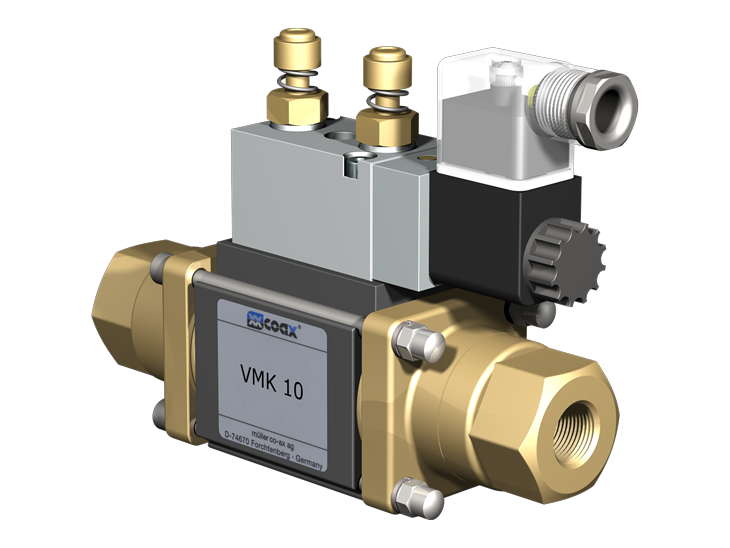

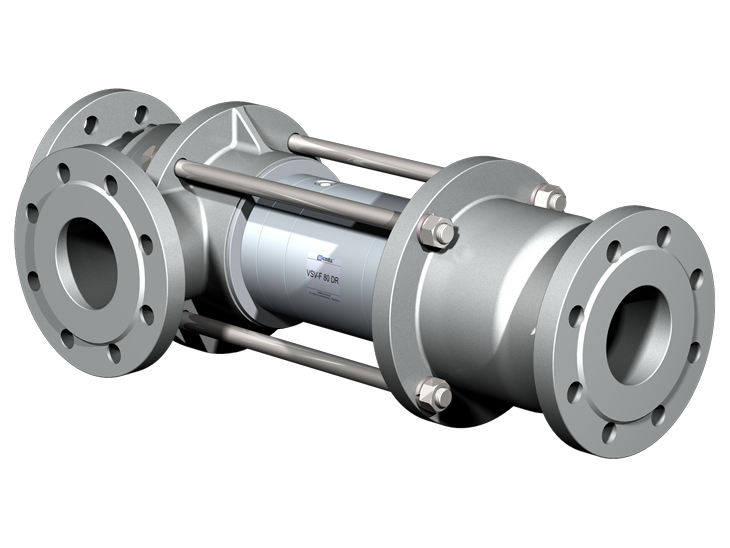

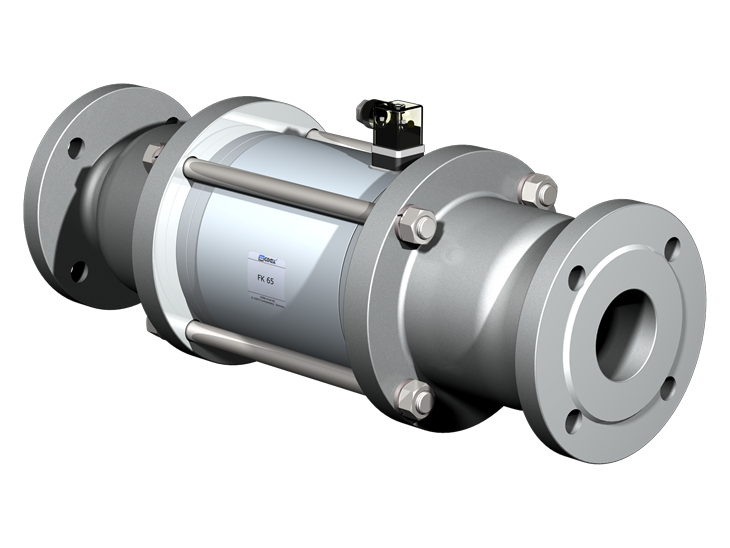

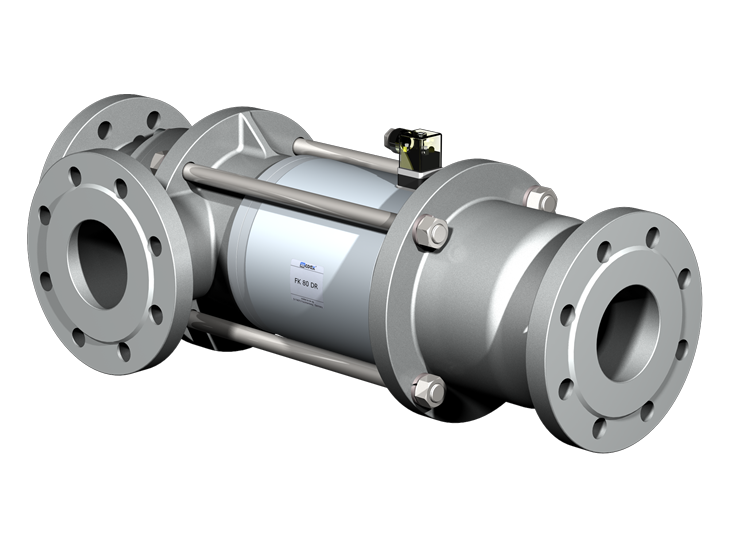

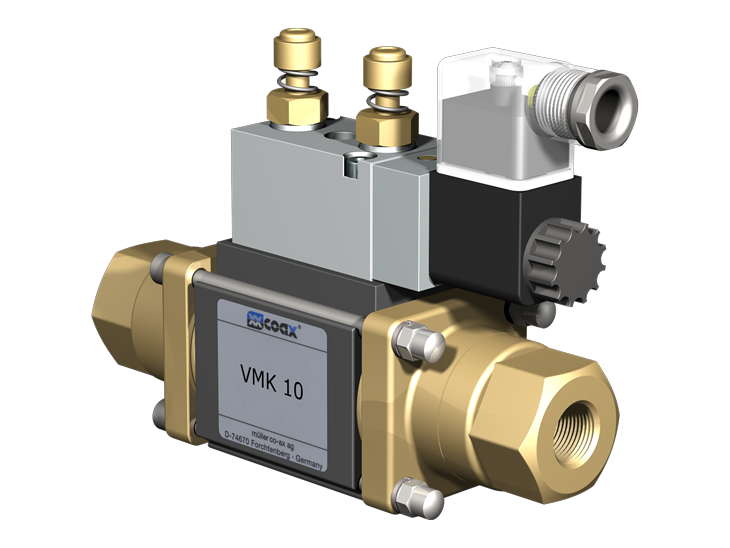

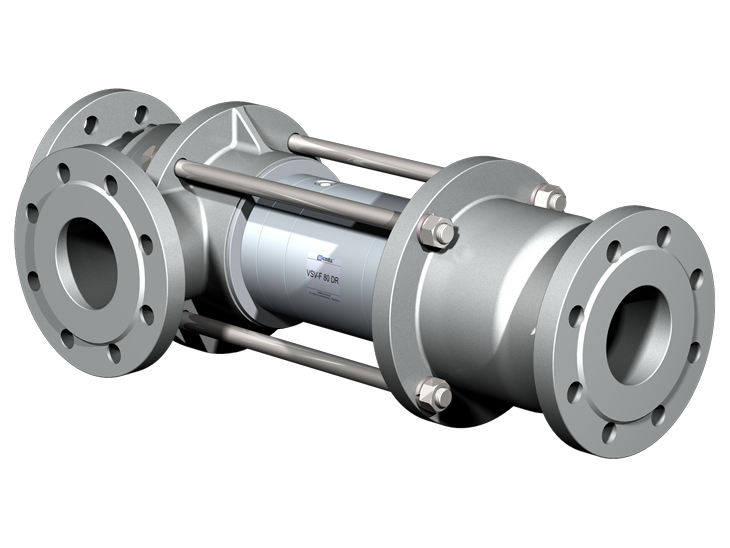

COMPACT SIZE

The compact size results from the unique coaxial valve design: the actuator is located around the control tube

The coaxial valve design provides a compact package by eliminating bulky actuators

The coaxial valves are fitting into the pipeline and are perfectly suitable for small installation space

FAST ACTUATION

Fast actuation and short switching times due to pressure balanced valve design

Repeatable switching in less than 30 milliseconds

For applications that require precise switching and a high number of switching cycles

BACK PRESSURE TIGHT

When the valve is closed, the pressure at the outlet side can be higher without any leakage due to the pressure balanced valve designs

For pneumatic or hydraulic operated valves, back pressures up to the full pressure level are possible.

For electric operated valves, back pressures up to 16 bar are possible.

Other valves such as check valves are not required.

BI-DIRECTIONAL OPERATION

The valve design allows the medium to flow through in both directions

Eliminating the need for multiple valves.

100% reliability for the operation in both directions.

CONTAMINATION RESISTANT

The coaxial valves are contamination resistant due the special valve seat design and only one moving part

No failure of the valves even with contaminated media.

Whether controlling vacuum or high pressure valve performance remains precise and dependable Process reliability.

100% tightness and with solenoid valves also to the outside.

Long lifetime and low maintenance.